After recognizing unusual pain or a medical diagnosis of a particular condition, it is quite possible that the treatment plan may recommend the use of any orthotic devices.

A foot orthotic will play the role of continuous help and support. In most cases, the treatment plan for the various foot conditions (e.g. flat foot, plantar fasciitis, arthritis, metatarsalgia, etc.) includes foot orthotics and an adapted pair of orthopedic shoes. Indeed, the main role of foot orthotics is to improve the function of your feet through the repositioning, support, and balance they provide. And of course, a good pair of shoes is essential in everyday life, whether worn alone or with foot orthotics.

Do you have any questions about the usefulness of this product, but also about its manufacture? This article will help you to see more clearly the different foot orthotics on the market, but also the steps involved in their manufacture.

What are the types of foot orthotics

The Bio-Dynamik® line of foot orthotics is manufactured according to the activity, morphology, and pathology of each individual. Médicus designs custom-made foot orthotics designed for running, our foot orthotics provide comfort and relief to painful and tired feet.

Depending on your foot problems, there are 6 types of Bio-Dynamik® foot orthotics:

- Perfostab: Excellent for running or dynamic walking

- Meditech: Ideal for weak arches, talalgia, mild arthritis or mild valgus

- Meditech Carbon: Perfect for very active people looking for superior support and stability

- DI-AR: Specially designed for people with diabetes or arthritis

- Dynafin: Recommended for people who work in a seated position and who want lightweight support suitable for wearing street shoes

- Pediatric: Specially designed to meet the needs of the child throughout his or her growth

All Medicus foot orthotics are custom-made to suit you, they will adapt to your small defects such as a smaller toe or a deformity of the feet.

They are made of high-quality materials that provide good absorption, stability and adequate adaptability, and propulsion properties, known as ASAP standards. ASAP standards are those to which each of the foot orthotics we manufacture or adjust must conform. The combination of different multicomponent elements and materials allows our Bio-Dynamik® orthotics to apply ASAP standards, ensuring a proven and unparalleled treatment plan effectiveness.

What are the manufacturing steps of the custom-made foot orthosis?

Because of its important daily role, the manufacture of foot orthotics should not be taken lightly, which is why we advise you to go to an orthotist for a biomechanical evaluation.

When the assessment is completed, two scenarios are possible:

- If you have a medical prescription: depending on the pathology found, the orthotist recommends the product, custom-made or prefabricated, best suited to the needs of your treatment plan.

- If you do not have a medical prescription: the orthotist will give you the detailed report of your assessment and may, if necessary, refer you for consultation with the appropriate health professional (doctor, physiotherapist, etc.).

If the treatment plan recommends the use of any orthotics, the casting and measurement are done for the laboratory design of your custom orthotics, which we will detail below:

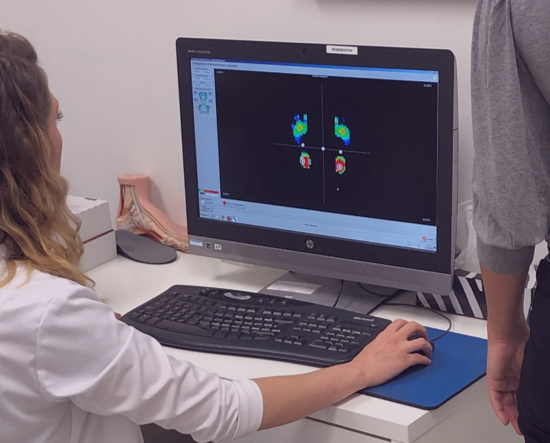

- Podography: after the postural assessment carried out during the biomechanical evaluation, the orthotist will then take the shape of your foot on a flat surface. He will then study the pressure points, the shape of the foot, but also the morphology.

- The impression-taking: the orthotist molds the feet in a block of polystyrene foam (foamcast)

- Design of the orthotic treatment plan: the orthotist will evaluate the type of orthotic that will best suit you. It will take into account the correction to be applied, the materials, the flexibility required, etc.

- The choice of materials: there are various types of coatings available, depending on your activities or the type of correction required. These include leather, foam, cork, leatherette, thermoplastic or ethylene-vinyl acetate (or EVA).

- The manufacture of the orthotics: the foot orthotics is made from plaster designed from the foamcast impressions. The orthosis is then manufactured and assembled from the casting and the materials and adjustments mentioned in the treatment plan. The last step of sandblasting and finishing is done.

- Delivery and testing: Once the manufacturing process is complete, the orthotist invites you to an appointment to test the orthosis in your shoe. Small adjustments to the orthosis can then occur (e.g. cutting, sanding, finishing). Depending on the pathology and type of orthosis, the orthotist works with the shoe consultant to recommend the best shoes.

- Adaptation: It takes about 1 month for the body to adapt to new orthotics. If discomfort persists after this period, it is important to make an appointment with your orthotist for an assessment.

- Follow-up: Your foot orthotics have been adjusted to suit your shoes and lifestyle. Their precise adjustment is essential to ensure their comfort over time. Your needs change and, to meet them, your orthotics must be checked annually.